When dealing with industrial piping systems, finding a solution that resists both corrosion and high temperatures while providing flexibility can be challenging. A corrugated compensator with a PTFE lining solves these problems, ensuring durability, flexibility, and long-term protection for sensitive systems. This article explains the benefits and applications of a PTFE-lined corrugated compensator.

What is a PTFE-lined corrugated compensator?

A PTFE-lined compensator is designed for handling corrosive media and extreme operating conditions. It features a flexible corrugated body with a durable PTFE lining, making it suitable for a variety of industrial systems that demand high levels of performance.

PTFE-lined compensators combine flexibility and chemical resistance, making them ideal for high-temperature and corrosive environments. These compensators are commonly used in industrial applications where chemical exposure and extreme conditions are present.

PTFE, known for its non-stick and corrosion-resistant properties, serves as the inner lining, providing a barrier against aggressive chemicals. Corrugated compensators, with their flexible design, absorb movements and vibrations, ensuring a stable connection in dynamic piping systems.

What does PTFE-lined mean?

PTFE lining refers to coating or layering materials with polytetrafluoroethylene (PTFE), a synthetic fluoropolymer known for its chemical resistance and low friction properties.

A PTFE lining protects pipes, compensators, or other equipment from chemical corrosion, wear, and high temperatures, making it perfect for harsh industrial environments.

PTFE-lined compensators are ideal for applications that involve highly corrosive fluids or gases. PTFE, being chemically inert, helps prevent internal erosion of piping components, extending the operational life of the equipment.

What is PTFE corrugated Teflon tubing?

Corrugated Teflon tubing, made from PTFE, is a flexible, durable solution used in systems requiring high compressibility and chemical resistance. Its corrugated design allows for exceptional flexibility, while PTFE’s properties ensure the tubing can withstand aggressive chemicals and extreme temperatures.

Corrugated PTFE tubing offers flexibility and compressibility, which is vital in dynamic piping systems that undergo movements, pressure fluctuations, or vibrations. Its resistance to high temperatures and chemicals makes it highly valuable in industrial applications.

Corrugated PTFE tubing is widely used in various industries, including chemical processing, pharmaceuticals, and food production, where it provides reliable protection against fluid flow and environmental contamination.

What is PTFE-lined carbon steel pipe?

A PTFE-lined carbon steel pipe involves coating the inner surface of a carbon steel pipe with PTFE to provide chemical resistance while maintaining the pipe’s structural integrity.

PTFE-lined carbon steel pipes combine the strength of carbon steel with the chemical resistance of PTFE, making them suitable for corrosive environments and high-pressure applications.

PTFE-lined pipes are commonly used in chemical processing plants, pharmaceutical industries, and water treatment facilities, where they resist corrosion, reduce maintenance costs, and improve system longevity.

What is the difference between PTFE and carbon-filled PTFE?

The primary difference lies in their composition: PTFE is pure polytetrafluoroethylene, while carbon-filled PTFE is a blend of PTFE with carbon particles. This blend enhances the material’s mechanical strength and wear resistance.

Carbon-filled PTFE offers better wear resistance and lower friction compared to standard PTFE, making it suitable for dynamic applications like seals and bearings where more durability is required.

Carbon-filled PTFE retains the chemical resistance and non-stick properties of PTFE but performs better in high-wear environments. It is commonly used in applications requiring frequent mechanical movement or where wear is a concern.

What does PTFE stand for?

PTFE stands for polytetrafluoroethylene, a synthetic polymer known for its non-stick, heat-resistant, and chemical-resistant properties.

PTFE, short for polytetrafluoroethylene, is a fluoropolymer used widely in industrial applications for its superior resistance to chemicals, heat, and friction. It is the key component in products like PTFE-lined compensators.

PTFE was first discovered by DuPont and is often referred to by its brand name, Teflon. Its properties make it a valuable material in a wide range of industries, including chemical processing, electronics, and manufacturing.

Summary

A PTFE-lined corrugated compensator offers outstanding resistance to corrosion, flexibility, and thermal stability, making it essential in various industrial applications. By combining the properties of PTFE with the durability of corrugated compensators, these devices effectively reduce stress on piping systems, extend their lifespan, and protect them from damage.

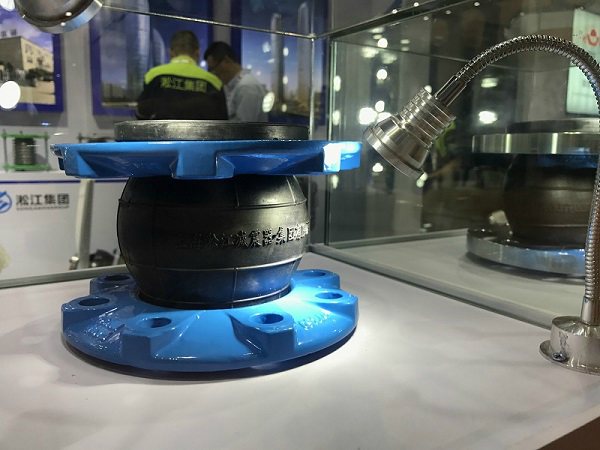

![[Exhibition hall] Take you to experience the rubber expansion joint Pn6 Pn10 Pn16 Pn25 exhibition hall](http://din-rubber-expansion-joint.com/wp-content/uploads/2022/06/Exhibition-hall-Take-you-to-experience-the-rubber-expansion-joint-Pn6-Pn10-Pn16-Pn25-exhibition-hall-1.jpg)